Hebei HYMAC Agricultural Machinery Co., Ltd. (hereinafter referred to as HYMAC) was established in 2009 and is located in Baoding, Hebei Province, China. HYMAC is a leading domestic manufacturer specializing in corn harvesting machinery, integrating independent R&D, manufacturing, sales, and service. Its main products include ear-picking and husking self-propelled corn harvesters as well as wheat harvesters.

HYMAC has been awarded numerous honors, including National High-Tech Enterprise, Hebei Provincial “Little Giant” Technology Enterprise, Hebei Technology-Based SME, Hebei Specialized, Refined and Innovative Enterprise, and Leading Enterprise in the Agricultural Machinery Industry. The “HYMAC” brand corn harvesters have been jointly recognized as a National User-Satisfied Brand by the China Agricultural Machinery Industry Association, the China Agricultural Mechanization Association, and the China Agricultural Machinery Distribution Association.

The company is also a participant in the formulation of national standards for corn harvesting machinery and operates the Hebei Provincial Corn Combine Harvester Technology Innovation Center. In 2022, HYMAC was awarded the Second Prize of the China Machinery Industry Science and Technology Progress Award.

Industry Challenges and Automation Demand

Bending processes for sheet metal parts in the agricultural machinery industry are typically characterized by large quantities, heavy workpieces, and complex structures. During peak farming seasons, rising machine demand often requires shift work and collaboration by two to three operators per bending station.

With increasing order volumes and the growing demand for green and sustainable manufacturing, traditional manual bending methods can no longer meet HYMAC’s production requirements or long-term development goals. Leveraging its deep expertise in automated bending solutions for the agricultural machinery industry, Derateck has delivered numerous successful projects, effectively addressing challenges such as high labor intensity and low production efficiency. By deploying robotic press brake cells, HYMAC significantly reduced labor intensity, lowered manpower requirements, and increased overall production capacity.

Press Brakes

To meet HYMAC’s single-sheet production requirements, Derateck provided two high-end and highly stable CNC press brakes: CBB-50/1650D and CBB-170/3200D.

To support HYMAC’s digitalized workshop management, the machines are equipped with the latest ESA 840R CNC system from Italy, featuring expanded digital and information interfaces. In addition, Derateck developed and implemented customized digital and information management functions, enabling seamless integration of bending cell data into HYMAC’s production management system for efficient production control and traceability.

Robot Selections

To ensure long-term, high-load production, and taking into account sheet size and weight, Derateck selected dedicated bending robots including the FANUC R-2000iC/210F and FANUC M-20iD/25 six-axis industrial robots. The operating load is controlled below 60%, ensuring stable, continuous 24/7 operation under full production conditions.

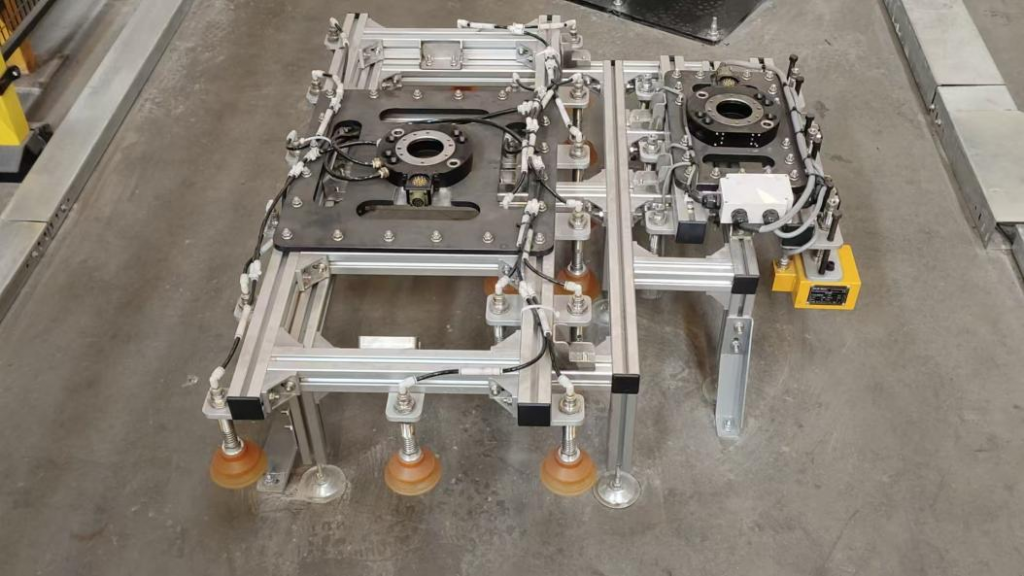

Gripper System

Based on HYMAC’s wide range of workpiece dimensions and heavy sheet weights, Derateck customized two different sets of robotic grippers for each press brake to accommodate varying part sizes.

The grippers combine multi-zone vacuum suction cups and electromagnetic grippers. For perforated and multi-hole sheet metal parts, electromagnetic or electro-permanent magnetic grippers are used to enhance gripping force and stability.

To address the diversity of sheet materials, a quick-change gripper system is employed, allowing the robot to automatically switch between different suction grippers. This significantly improves production flexibility, reduces manual labor when changing heavy grippers, minimizes downtime, and eliminates the need for re-teaching after gripper replacement. Once the gripper is changed, the corresponding program can be called directly, and suction zones are automatically selected according to the preset sheet size and bending program.

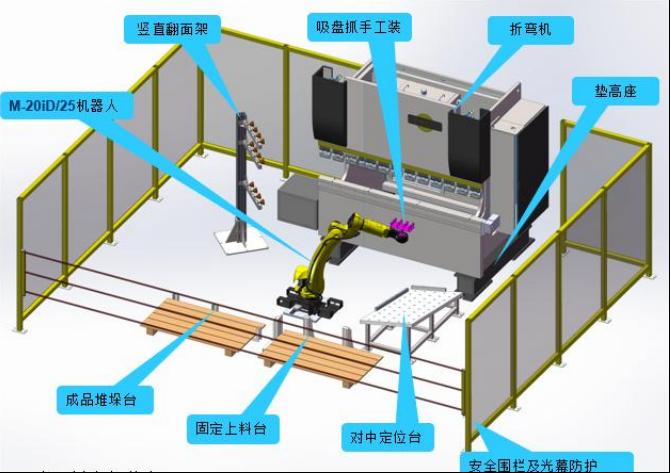

Unit Layout and Safety Design

The robotic bending unit is equipped with a FANUC six-axis robot capable of fully automated processing from raw material loading to finished bending parts. With an external worktable and quick-change gripper system, program switching and gripper replacement can be completed outside the robot’s working envelope, eliminating the need for operators to enter the robotic area.

This layout significantly improves operational safety while simplifying material loading, unloading, and routine maintenance.

Project Implementation and Results

Derateck’s automation team provided HYMAC with one-stop services, including solution planning, equipment configuration, installation and commissioning, as well as operator training. After the bending cell was officially put into production, the system quickly achieved the expected performance targets.

HYMAC robotic bending unit represents another successful application of Derateck automation solutions in the agricultural machinery industry. It effectively addresses challenges such as large sheet sizes, heavy materials, and complex perforated parts, earning high recognition from HYMAC.

Expanding Automation Capabilities

In addition to robotic bending unit, Derateck also offers a wide range of automation solutions, including flexible sheet metal processing lines, laser storage and tower systems, and automated loading and unloading systems for punching machines.

With multiple proprietary intellectual property rights and extensive project experience, Derateck remains committed to delivering high-efficiency, high-reliability products and services to customers worldwide.

DERATECH

DERATECH

您好!Please sign in