As competition in the sheet metal fabrication industry intensifies, unstable processing accuracy, low production efficiency, and high equipment maintenance costs have become major obstacles preventing many manufacturers from improving quality and efficiency. How can companies achieve a leap in productivity without compromising machining quality?

After dedicated R&D and extensive real-world testing, Derateck officially launches the Future Series high-speed flat-bed laser cutting machines. Starting from customers’ core pain points, Derateck delivers an optimal solution that balances both efficiency and precision through four key technological advantages, empowering metal processing enterprises to break through capacity bottlenecks.

Say Goodbye to High-Speed Vibration — Precise, Stable, and Built to Last

Traditional cutting machines often suffer from vibration and positioning deviations during high-speed operation due to large inertia and cutting head instability, severely affecting product quality.

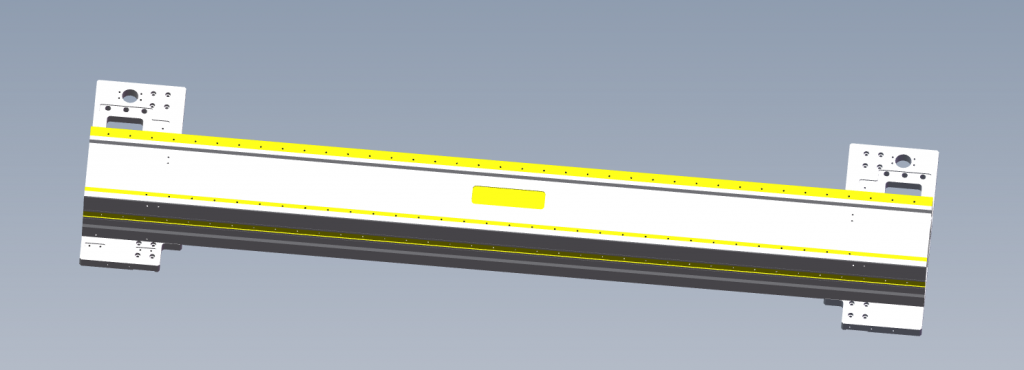

The core breakthrough of Derateck Future Series lies in its lightweight aerospace-grade extruded aluminum crossbeam. This aerospace-grade material combines exceptional strength with reduced weight. Together with a low center-of-gravity design and Derateck’s self-developed cutting head mounting structure, operating inertia is significantly reduced, ensuring smoother high-speed motion.

This design effectively eliminates cutting head vibration under high-speed conditions, allowing the cutting head to remain perfectly synchronized with the crossbeam at all times—guaranteeing consistent cutting accuracy even during rapid movements.

No More Stalling — Faster Start-Stop Response for Complex Cutting

Stuttering during complex contour cutting and slow start-stop response are key factors limiting productivity. Derateck Future Series addresses these challenges head-on with a customized high-dynamic transmission system, delivering a revolutionary processing experience.

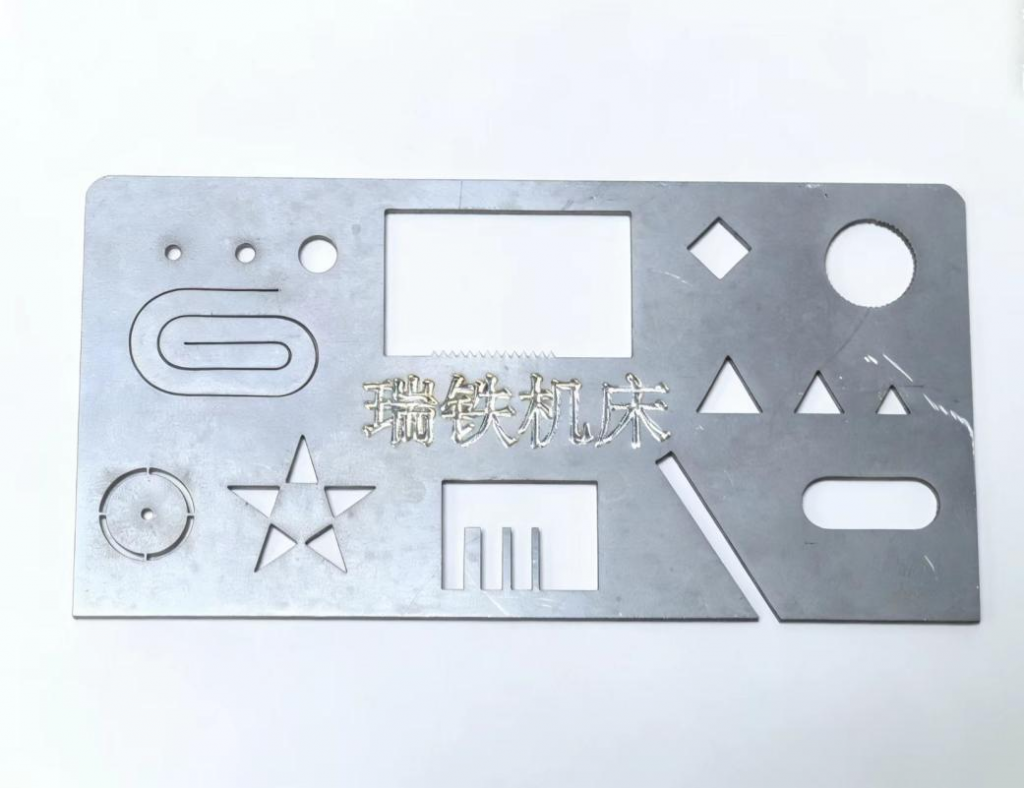

High-precision gear reducers within the transmission system have undergone tens of thousands of durability tests, offering a service life far exceeding that of conventional reducers. Optimized transmission ratios significantly improve positioning and start-stop responsiveness, enabling smooth, uninterrupted cutting even for complex geometries.

In addition, customized high-performance servo drives are perfectly matched with high-inertia motors. The servo system works in close coordination with the cutting system, ensuring high stability and accuracy even under high acceleration. Cutting paths remain precise, completely eliminating vibration-induced deviations and ensuring every finished part meets stringent quality standards.

Resistant to Deformation — A Rigid, Durable Machine Bed

The machine bed is the “foundation” of any cutting system, and its stability directly determines machining accuracy. Derateck Future Series features a fully welded, one-piece heavy-duty bed, offering significantly enhanced rigidity and long-term resistance to deformation.

A multi-point leveling foot design allows flexible adaptation to different workshop floor conditions, effectively distributing machine stress and ensuring rock-solid stability during operation.

To address the high temperatures generated during laser cutting, heat-resistant and fireproof materials are installed specifically in the cutting zone. This prevents thermal deformation of the bed, further safeguarding machining accuracy, extending overall machine lifespan, and reducing long-term maintenance costs—making production more reliable and worry-free.

Efficiency Boost of 40%–50% — Immediate Cost Reduction and Productivity Gains

While maintaining superior quality, improving efficiency is critical to staying competitive. Derateck Future Series delivers a disruptive leap in performance:

Maximum rapid traverse speed of 150 m/min, dramatically reducing non-cutting time—especially ideal for batch processing of multiple parts

1.5G acceleration and a 7 Hz processing low-pass frequency, ensuring smoother, more continuous cutting motion

Extensive testing shows that overall processing efficiency is improved by 40%–50% compared to traditional flat-bed cutting machines. This means enterprises can meet the same production demands with fewer machines, lower operating costs, and significantly higher output—creating greater value in less time.

From robust structural design to outstanding performance, Derateck Future Series high-speed flat-bed laser cutting machines comprehensively meet modern manufacturing’s demands for precision, efficiency, and durability. Widely applicable across sheet metal fabrication, automotive components, construction machinery, and many other industries, the Future Series is the smart choice for manufacturers seeking high-efficiency production and precision machining.

Choose Derateck Future Series—choose efficiency, accuracy, and a decisive edge in tomorrow’s competitive market.

DERATECH

DERATECH

您好!Please sign in