Today marks the successful conclusion of the Derateck 2025 Open House. Customer representatives and industry experts from across the country gathered at Derateck, with some overseas guests making a special trip to attend. Together, they witnessed Derateck’s latest breakthroughs and innovations in the field of intelligent sheet metal equipment. The event was vibrant and received enthusiastic responses.

This was more than just a showcase of manufacturing capabilities—it was a deep exchange focused on technology, collaboration, and the future.

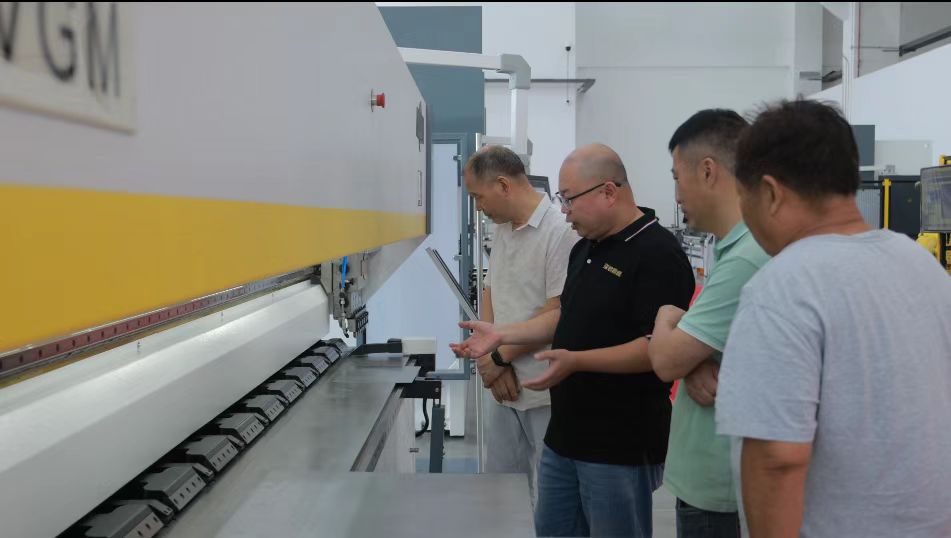

An Immersive Visit: Feel the Pulse of Intelligent Manufacturing

Guided by our staff, guests toured Derateck’s modern intelligent factory and Global Marketing & Technology Center.

The efficient production lines, precision machining equipment, and standardized workflows left a strong impression on all. Meanwhile, the demonstration of equipment solutions and a comprehensive service system at the showroom highlighted Derateck’s growing capacity for integrated delivery.

Many guests commented, “This Open House was not just about seeing the machines—it revealed the systematic logic behind manufacturing. It truly strengthened our confidence in Derateck.”

Two Breakthrough Technologies Debut to Rave Applause

A major highlight of the event was the official launch of two independently developed, highly anticipated core technologies:

TAM-D Dual-Speed Press Brake

In response to the challenges of alternating between large and small parts during production, Derateck has developed the TAM-D dual-speed press brake.

When processing large sheets, it operates in standard mode at about 18 bends per minute. For small sheets, the high-speed mode delivers up to 30 bends per minute.

This innovative solution attracted widespread interest, with many customers remarking that it “perfectly matches the demands of modern production rhythms.”

Hydraulic Automatic Clamping System

Derateck’s newly developed hydraulic automatic clamping system combines hydraulic transmission with mechanical clamping, enabling fast and secure upper die changes. The built-in mechanical self-locking mechanism ensures that the clamping remains firm even if hydraulic pressure drops.

It also supports vertical clamping—simply pull the front pressure plate ring to vertically change the upper die at any position, offering unmatched speed and convenience.

This function drew immediate attention from customers with frequent tool change requirements.

Technical Seminars: Idea Exchange Drives Collaboration

During the afternoon’s technical exchange session, Derateck’s technical team engaged in in-depth discussions with customer representatives on topics such as improving sheet metal processing efficiency, building intelligent production systems, and future equipment trends.

Customers shared valuable insights based on their own experience, and some even reached preliminary cooperation agreements on the spot. This productive dialogue underscored Derateck’s commitment to being customer-centered.

The event was marked by high energy and active participation. Long-term partners attended to exchange insights, while many first-time visitors expressed strong interest after their tour.

We extend our heartfelt thanks to every guest who joined us—your presence made this event special. Your support inspires us to keep growing and moving forward.

DERATECH

DERATECH

您好!Please sign in