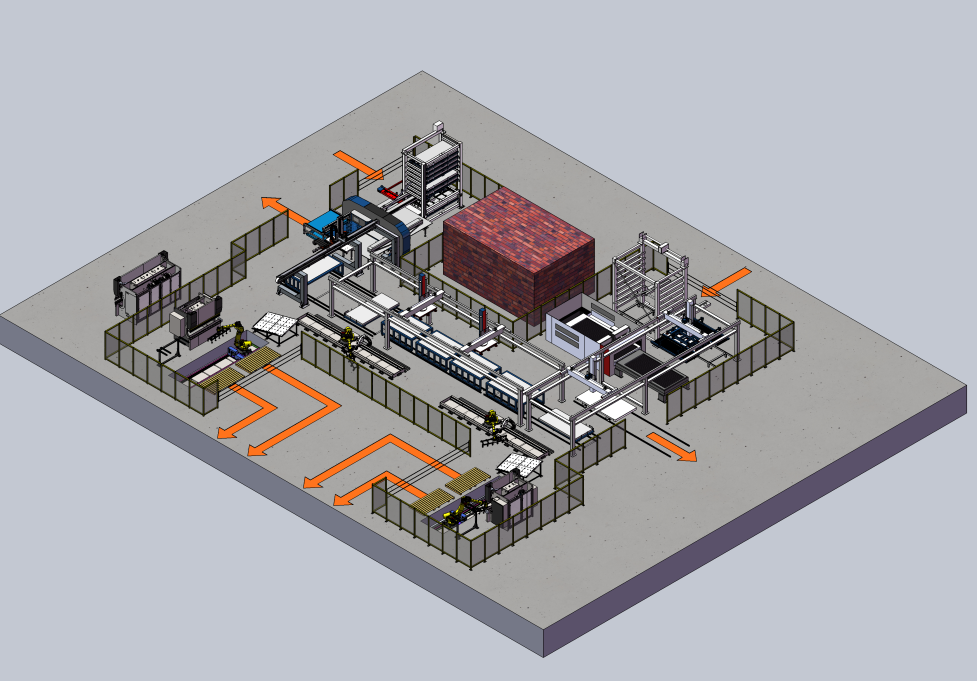

Today, we’re introducing an automated production line solution provided by Derateck for a well-known sheet metal enterprise. The line consists of four main units:

Cutting Unit: Centered on a FUTURA3015/6000W fiber laser cutting machine, equipped with a tower storage system and an automatic loading/unloading device.

Punching Unit: Centered on a DINAMICA3.1550 servo CNC turret punching machine, also equipped with a tower storage system and an automatic loading/unloading device.

Intermediate Transfer Unit: A gantry-type sorting system for sheet transfer, equipped with upper and lower electric carts for transportation and buffering.

Automatic Bending Unit: Comprising two hybrid pumps control CNC press brakes and a FANUC robot, completing the final forming process.

The central control unit decomposes and assigns production tasks, coordinates the progress of each unit, and ensures stable, efficient operation of the entire production line.

This sheet metal automation line has now entered the delivery and commissioning stage. We look forward to seeing its successful start-up, and we’ll keep you updated with the latest progress.

DERATECH

DERATECH

您好!Please sign in