- What are the basic principles of laser equipment anti-freezing?

When the coolant temperature drops below its freezing point, the cooling water solidifies and expands, which can block or rupture the cooling pipes, damaging internal and optical components of the laser. In severe cases, it may cause permanent damage to the laser source. Therefore, proper winter anti-freeze measures are essential.

- What are the operating temperature requirements for the laser in winter?

The laser’s working environment temperature should be maintained at around 22°C.

The low-temperature water of the chiller should be set between 20–24°C,

The high-temperature water between 28–30°C.

Before laser emission, the chiller should run for at least 20 minutes to ensure the actual water temperature reaches the set value.

- What are the common anti-freeze methods for laser equipment?

- Keep the chiller running (depending on local temperature)

If continuous power supply can be guaranteed, keep the chiller on so the coolant remains in circulation. However, note that in extremely low temperatures, even flowing water may freeze.

- Drain the coolant (for long-term machine shutdown)

This method is suitable for long-term shutdowns, such as during holidays.

Disconnect the chiller’s low-temperature and normal-temperature water outlet pipes, use clean air to blow through the outlets to remove coolant from the chiller, laser source, and cutting head pipelines. Then, open the drain port to completely empty the coolant from the chiller tank and pipelines. This prevents pipe or equipment damage caused by freezing.

- Use antifreeze as coolant (for unstable power supply)

When the ambient temperature is below freezing and power outages are frequent—making it impractical to drain coolant daily—antifreeze must be used.

Recommended antifreeze brand: Clariant (USA).

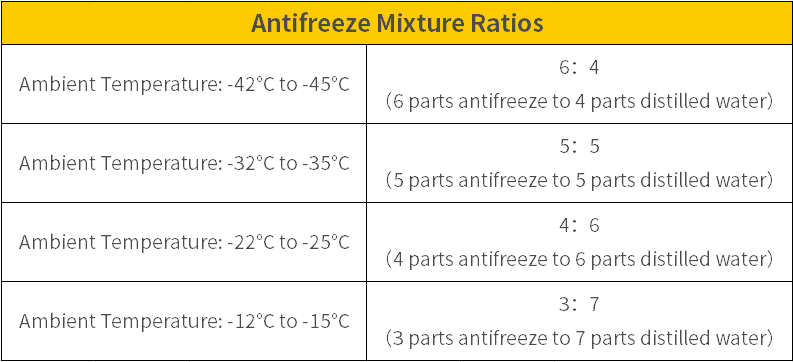

Do not add antifreeze directly into the chiller. Mix 30% antifreeze with 70% distilled or deionized water, stir evenly, and then pour into the chiller. This prevents pipe corrosion and ensures the coolant remains liquid down to -15°C.

The chiller’s operating temperature should stay above 5°C, and the cold start temperature must be above 10°C.

- Maintain ambient temperature

When possible, use heating equipment to keep the ambient temperature above 0°C, with 5°C being the ideal working environment.

Warm Reminder:

Antifreeze cannot fully replace distilled water and is not recommended for year-round use. After winter, it’s advisable to flush the system with distilled or deionized water and use it as the regular coolant during normal operation.

DERATECH

DERATECH

您好!Please sign in