In the architectural façade and metal decoration sectors, aluminum panels have become a material of choice thanks to their light weight, aesthetic appeal, and excellent formability. They are widely used in high-end commercial complexes, metro and airport facilities, and public buildings. However, as market demand becomes increasingly diversified, aluminum panel production is facing new challenges:

– A wide variety of product types and specifications

– Complex non-standard shapes with high precision requirements

– Tight delivery schedules and low efficiency in manual operations

Traditional manual bending methods struggle to meet both efficiency and quality when dealing with frequent model changes or large-size panels. Leveraging years of expertise in sheet metal automation, Derateck has launched a robotic bending unit specifically adapted for the aluminum panel industry—offering a flexible, efficient, and intelligent bending solution.

Success Story: A High-Efficiency Transformation for an Aluminum Panel Manufacturer

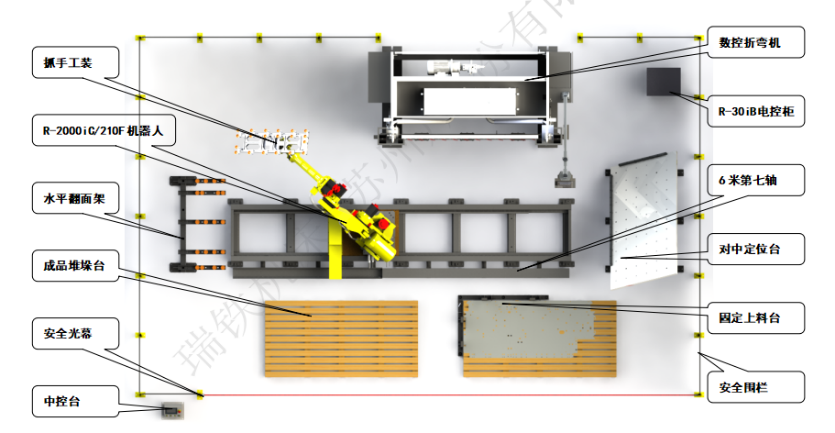

Derateck provided a fully customized robotic bending unit for a major aluminum panel processing company.

Built around the core workflow of automatic loading + gravity-based centering + intelligent bending + automatic unloading, the Derateck robotic bending unit fundamentally reshapes traditional production patterns.

The system integrates Derateck’s high-precision TAM-S series press brakes, paired with the stable and reliable Swiss Cybelec CT15win 6-axis CNC system and a FANUC 210 robot from Japan, achieving fully automated production from raw material loading to finished bending. In actual operation, the system automatically handles positioning, bending, and transferring of large or irregular panels—effectively solving pain points such as difficult manual handling, large positioning errors, and slow production beats.

These innovative designs enable the bending unit to easily adapt to the industry’s typical “multi-spec, small-batch, fast-delivery” production model.

In an era where customization and high-quality production go hand in hand, competition in the aluminum panel industry extends beyond aesthetics—it lies in manufacturing efficiency and the level of intelligent automation. Derateck will continue to drive innovation and focus on smart equipment, providing customers with more efficient, reliable, and scalable automation solutions.

Smart manufacturing empowers better bending. Choose Derateck for higher efficiency and superior quality!

DERATECH

DERATECH

您好!Please sign in